·Assure a part production within the target tolerance

·Optimize the cycle time

·Assure and maintain a constant and controlled productivity

· Compensate any production drift

·Track production history

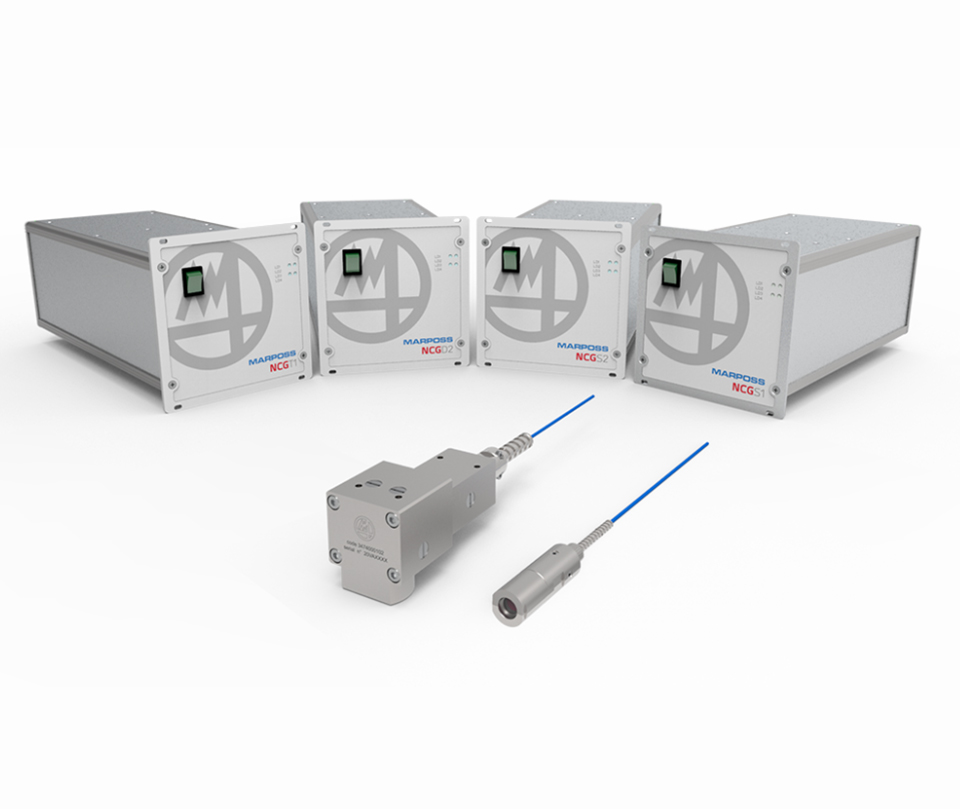

NCG unit

NCG interferometric gauges have been designed to be flexible and easy to use. Every single unit can be connected in a network of sensors controlled by a machine. Dedicated elaborations are available to measure both very reflective, rough or opaque parts. Thanks to its improved electronics it is possible in run time to execute measure and store hours of continuous data that can then be used for a post-process elaboration, quality control and machine performance evaluation.

|

Measuring principles |

Interferometric |

|

Measure type |

Thickness, distance |

|

Light source |

SLED |

|

Measure range* |

S1 = 37÷1850 µm S2 = 74÷3700 µm T1 = 15÷900 µm D2 = 60÷3000 µm |

|

Accuracy |

≤ 1 µm |

|

Axial resolution |

30nm |

|

Channel |

1 |

|

Interfaces |

Ethernet (10/100 Mbit) RS232 / RS422 as option |

|

Internet connection |

Yes |

|

Power supply |

12~24 Vdc (+20%/-15%) |

|

Power consumption |

30W |

|

Protection degree (IEC 60529 standard) |

IP40 |

|

Weight |

2,8 Kg |

|

Dimension [mm] |

127 (w) x 129 (h) x 255,5 (d) |

The above performances has been tested in static measurement. The measure performance is granted in the range of 15÷35 °C

* = range at refractive index n=1. To obtain the measure range for other materials, devide the range for the refractive index of that material. The measure range could be limited in case of rough surfaces with R a> 0.1.

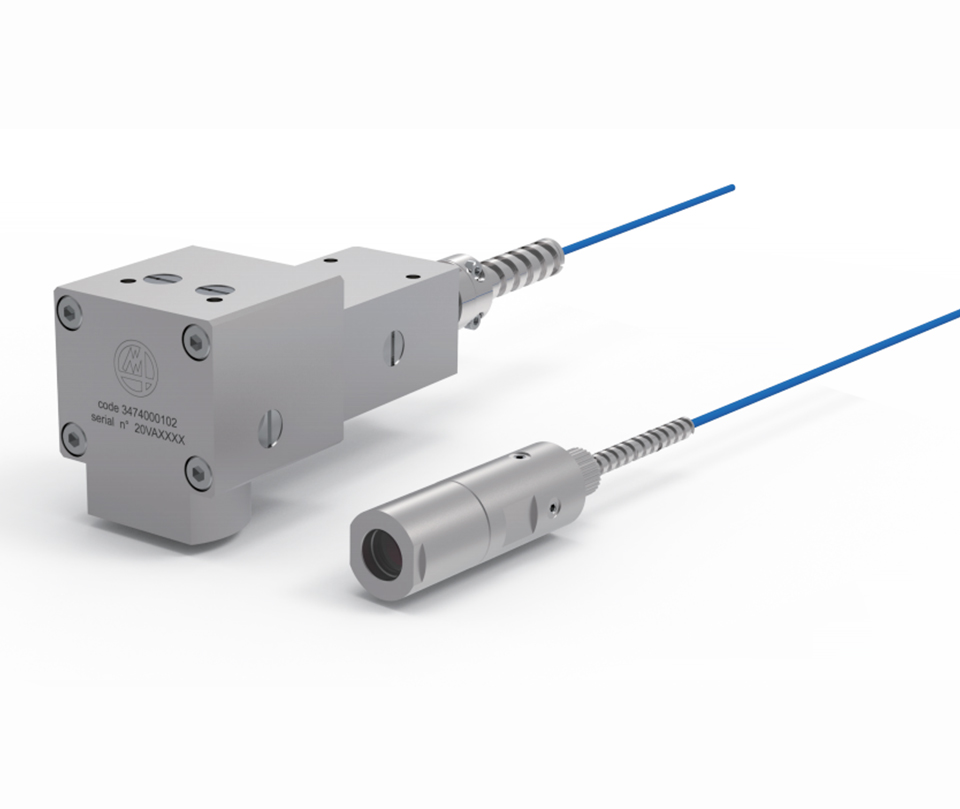

Optical probes

Marposs optical probes are designed to get the best performances in both very clean and harsh environment. Probes can be used even in presence of water or other aggressive substances too. Every single component has been tested to be reliable in case of vibrations, heat and humidity. Mechanical layout can be customized according to Customer requirements and can be used to measure both part thickness and distance.

|

Measure type* |

Thickness |

|

|

Working distance(WD)** |

1.6,10,100mm |

|

|

Spot diameter |

18÷30 µm |

|

|

Lateral resolution |

9÷15 µm |

|

|

Angle to surface |

90˚± 2° |

|

|

Optical fiber length |

3 / 4 m |

|

|

Optical fiber bending radius |

30mm |

|

|

Shielded fiber |

Option |

|

|

Protection degree |

IP68 |

IP40 |

|

weight(without cable)) |

915g |

80g |

Description

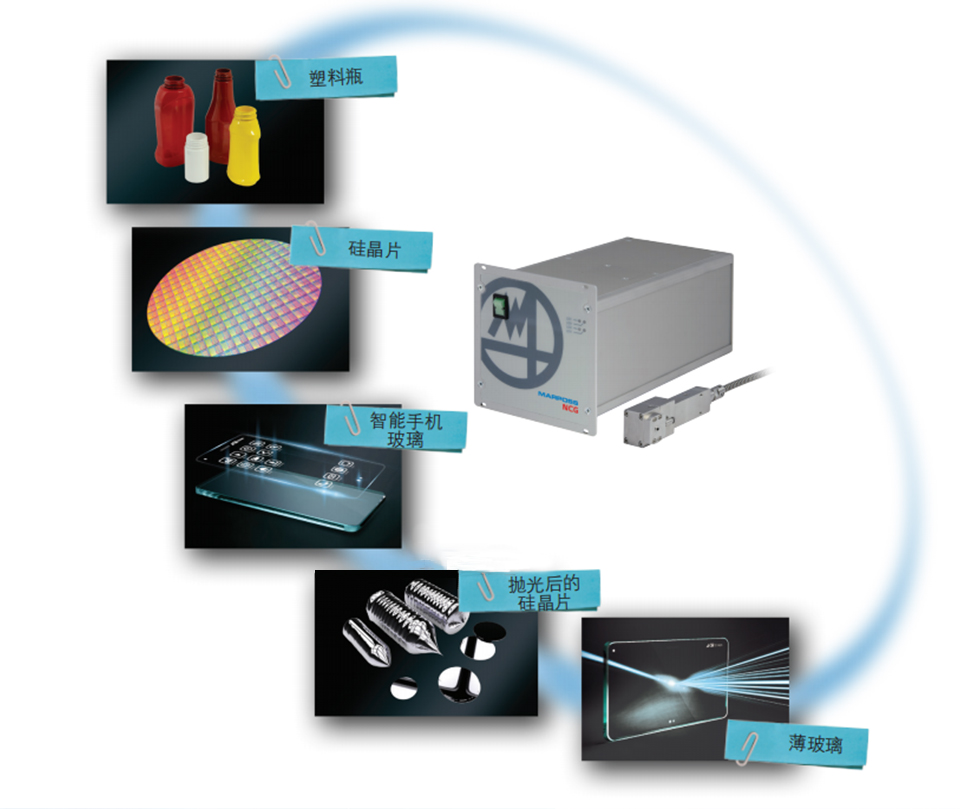

Marposs NCG gauge is a gauge to measure thickness based on interferometric technology: light waves, which are reflected at the layer boundaries of different surfaces of the object being measured, are brought to interference and the layer thickness is then calculated. The gauge has been designed to control the thickness of different type of parts, glass, plastic and silicon wafers. Thanks to the infrared light source is possible to measure none transparent materials too.

Our gauges are designed to improve and maintain machine cycle times, quality of the final product and to control the process before, during or after key operation steps.

Marposs NCG is a high-speed elaboration gauge that can be connected to any machine for accurate and fast part thickness control. It could be used on a fixture or inside a machine, in dry or wet environments within the limits specified in the technical data.

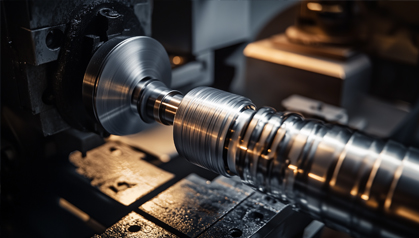

Typical applications

• Different type of silicon, sapphire wafers thickness measurement

• In-process control on back-grinding and lapping machines

• Thin and thick layers detection

• Tape thickness control

Benefits

• Assure a part production within the target tolerance

• Optimize the cycle time

• Assure and maintain a constant and controlled productivity

• Compensate any production drift

• Track production history

Contact us