·It is super - FAST

·EASE of USE - designed for customer use

·Precise, accurate measurements

|

Technical Parameter |

Optoflash S10 |

Optoflash S20 |

Optoflash S30 |

|

Measuring Range (Max Part Dimension) Length (mm) Diameter (mm) |

100 [100] 60 [90] |

200 [200] 60 [90] |

300 [300] 60 [90] |

|

Max Part Weight(Kg) |

6 |

||

|

Measuring Uncertainty 1 Length(mm) Diameter(mm) |

U95(2+L[mm]/200)µm U95(1+D[mm]/200)µm |

||

|

Part Load Mode |

Manual and Automatic (by Robot) |

||

|

Part Rotation |

Option |

||

|

Measurement Mode |

Static and Dynamic |

||

|

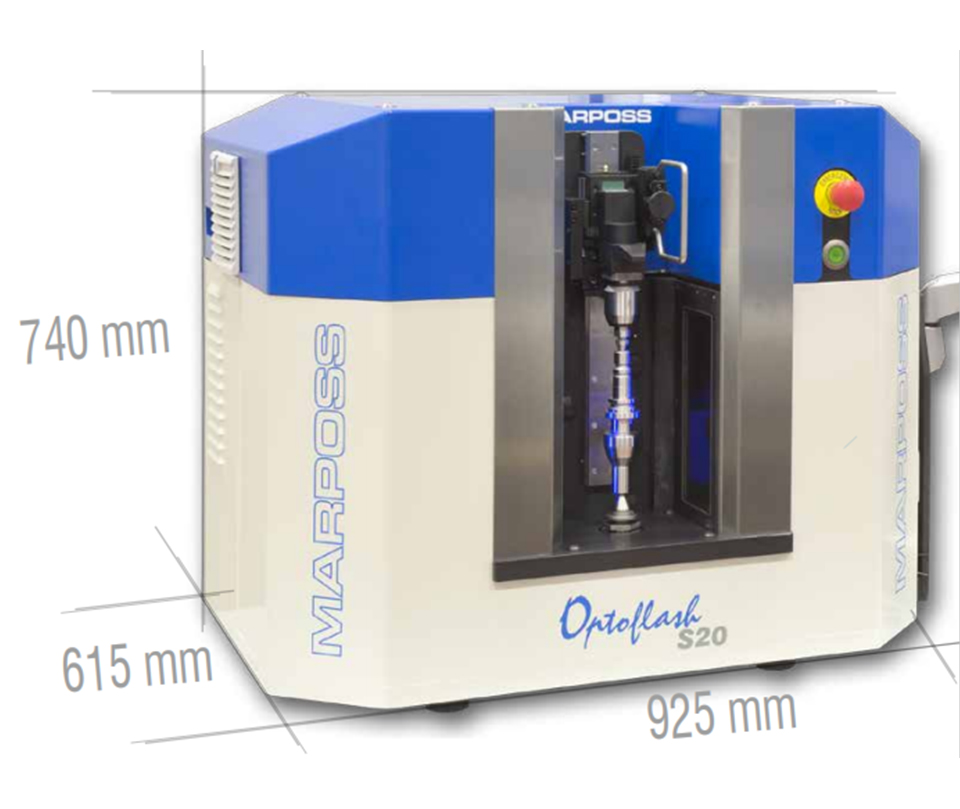

Dimension of Measuring System L x W x H (mm) |

925 x 615 x640 |

925 x 615 x740 |

925 x 615 x840 |

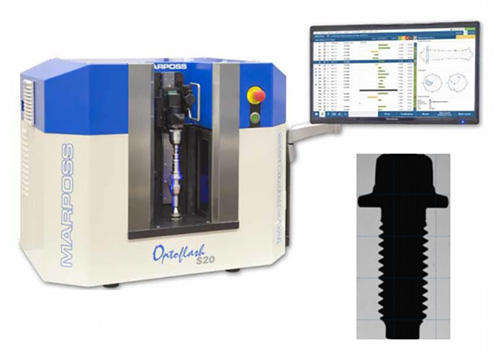

OPTOFLASH is the latest Marposs addition to its optical measuring systems. Designed for small-size shafts, fasteners and dental implants, Optoflash is the perfect solution for accurate quality control in the laboratory as well as in the production environment.

Optoflash is the world’s-first optical measuring unit - with axial range up to 300 mm - based on multiple 2D sensors in a fixed position. This means that images that are acquired by different sensors are perfectly combined together in order to generate one single resultant image of the part. This gives zero discontinuities and no gaps at the stitching edges.

With the absence of Z-axis movements Optoflash S is extremely fast and guarantees consistent and stable measurement performance over millions of cycles. The measurement cycle time is impressively fast and it can perform 100 static measurements in just 2 seconds - irrespective of how the measurement sections are distributed along the shaft length!

Thanks to its graphical user interface, anyone can use and also configure new measurements on the Optoflash. Features like smart results visuals, part detail images and graphic setups allow operator to quickly validate parts in production and also to detect the causes of non-compliances.

Used for quality control of small shaft parts, fasteners, medical implants and other production processes, easily solve a variety of common measurement problems

Contact us