·Leak test up to 30 bar and in vacuum

·Resolution up to 0.1 Pa

·7” colour LCD with touchscreen

·300 test programs

·Electronic pressure regulation

·Digital I/O interfaces for PLCs, RS232/ RS485 serial lines

·USB for PC and Ethernet

|

Power Supply |

External 24VDC; alternatively 85÷264V AC, 35W |

|

Air source requirement |

Dry, non-condensing, 5-micro filtered and oil-free air, compliant with ISO8573-1 |

|

Sensor calibration |

The sensor is calibrated by professional personnel with calibration equipment according to calibration information of the calibrated instrument |

|

A/D converter |

24 |

|

Pressure Regulator |

Electronic pressure regulator, with dedicated pressure transducer to visualize the regulated pressure on the display |

|

Keyboard |

Resistive touch screen |

|

Display |

7” color TFT LCD display with touchscreen |

|

Indicators |

4 LED lights (testing phases, pass/reject to outcome) |

|

Test counter |

Passed and rejected totals, resettable to zero Statistic option: mean value, minimum, maximum, standard deviation, normal distribution, CP, CPK, hour production totals |

|

Audible alarm |

Built-in beeper with programmable duration |

|

Clock |

Date and time, with super capacitor, max autonomy 7 days |

|

Programmable parameters |

300 testing tables with sequential mode, general parameters, volume calculation, leak rate ( icm3/min or cm3/h) |

|

PLC connection |

8 photocoupled inputs and 8 photocoupled outputs; Each I/O is fully programmable; Control of external automation (coupling, security cage,etc) without PLC |

|

Data interfaces |

Configurable RS232/RS485 serial lines; USB interface and Ethernet Protocols: modbus RTU, CSV ASCII output, barcode, QR code, printer |

|

Staubli® Connector |

Standard connector for Leak Master |

|

Housing |

Aluminium alloy housing |

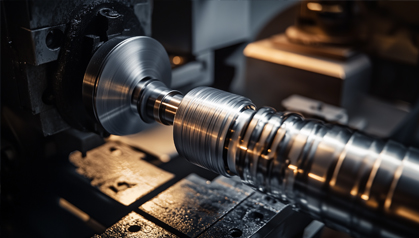

PROVASET T3LP is an innovative device for leak tests by absolute pressure decay measurement. The touch interface, with the color display and the testing real-time view, make the programming and use simple and immediate.Its high measurement resolution and test accuracy, together with the electronic regulation of the filling pressure, allow to perform not only leak tests but also distructive burst test, safety valves opening checks, volumetric control, obstruction tests and “in bell” tests on sealed products or by interception method.

The control of external automations, the interface with barcode readers and printers and the possibility to record the tests on USB memories or via ethernet make it a complete and suitable instrument for the most modern production applications.

It is used in industrial production department and quality laboratory to carry out leak detection gas flow test on automatic equipment and turntable.

Contact us